yellow brown:

This is the L-Can.The time per division was 5 micro seconds and the voltage per division was 1v.

Yellow black:

This is the H-CAN.I had a time per division of 5 micro seconds and a voltage per division of 1v.

Aliasing is jaggering,stairstep effect on curved or diagonal lines that are reproduced in low resolution as on a computer prinstious or division.This is how I got it on the dictonairy but it basically means that it is not clear.These waveforms are not aliasing because they are clear we have no trouble seeing and identifying them.

In the L-CAN the main voltage on the line is 2.5v.The other voltage is 1.4v.In the H-CAN has a main voltage of 2.5v and another voltage of 3.5v.this means voltage goes up to talk and on L-CAN voltage goes down.The reason for this is because the H-CAN more important.

compare with dc volts or ac volt setting:

2.6v

DC 2.3v

AC 0.1mv

Scan tool observation:

Stil using same vehicle.With a autoboss scan tool.

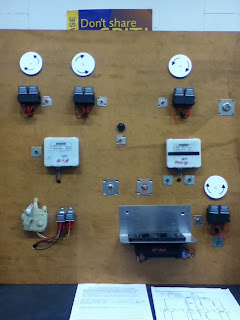

Different functions to examine can system:

controll unit version

fault codes

actual values(all selected)

actual values(manual selection)

actuations

different systems controled on can:

lights-low speed

wiper-low speed

washer fluid-low speed

central locking-low speed

airbag-high speed

window-low speed

instrement cluster-high speed

ABS-high speed

mirrors-low speed

aircon-low speed

Above is the wiring diagram for the range rover fast CAN

Above is the wiring diagram for the range rover low speed CAN.

Got the pictures above from:

http://ttec4826-vlad.blogspot.com/2011/06/can-multyplexing-worksheet.htmlHad to locate a system that goes to sleap after a short time.I found the can system does this.

voltage when the system is awake is 2.5v-2.6v.The voltage when system is asleep is 0.2mv.The voltage change on the yellow brown wire.Things like keyless entry is what wakes up the system when it is in sleep mode.